Machine Design

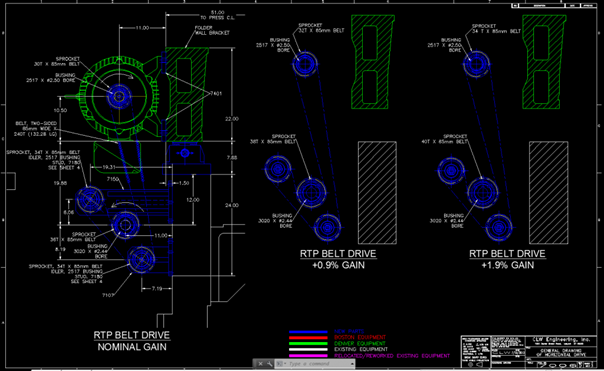

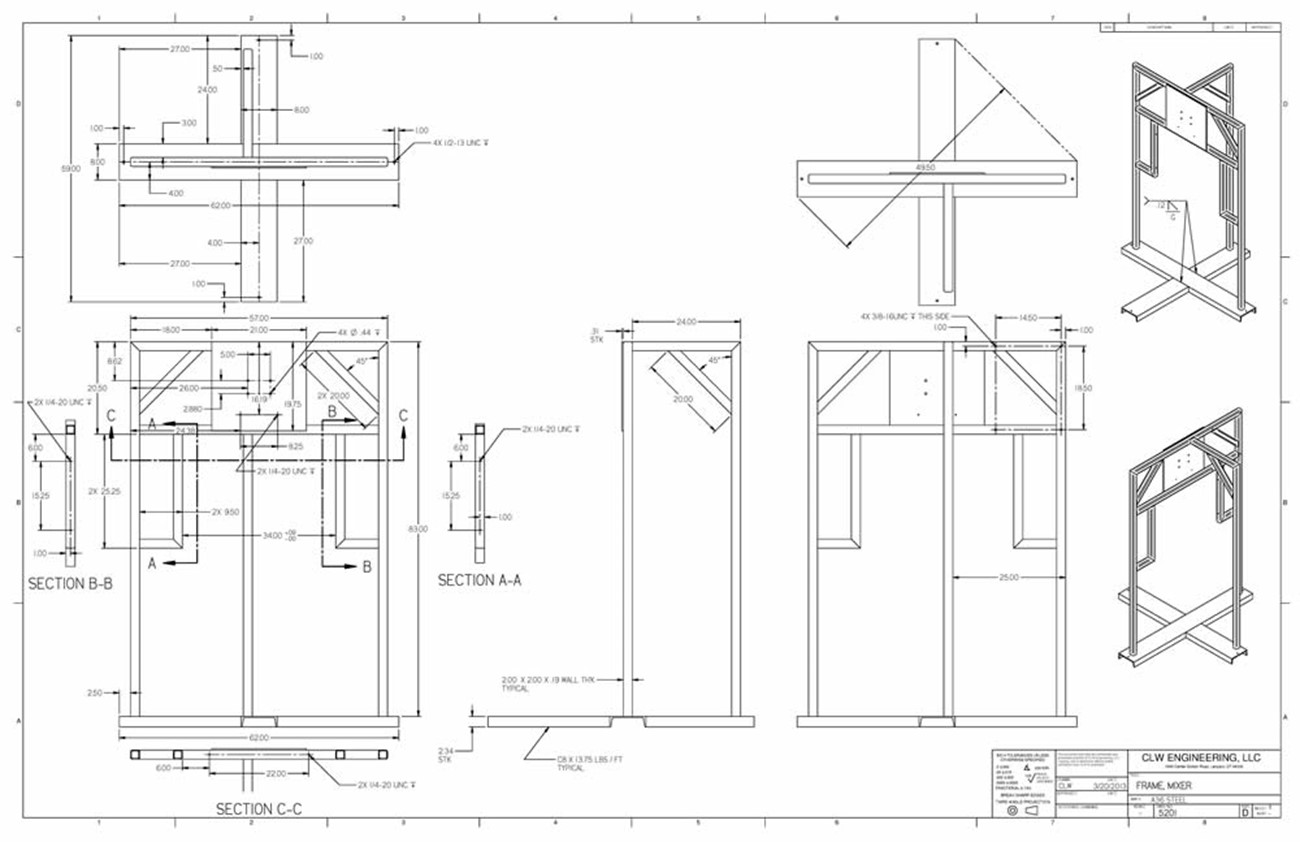

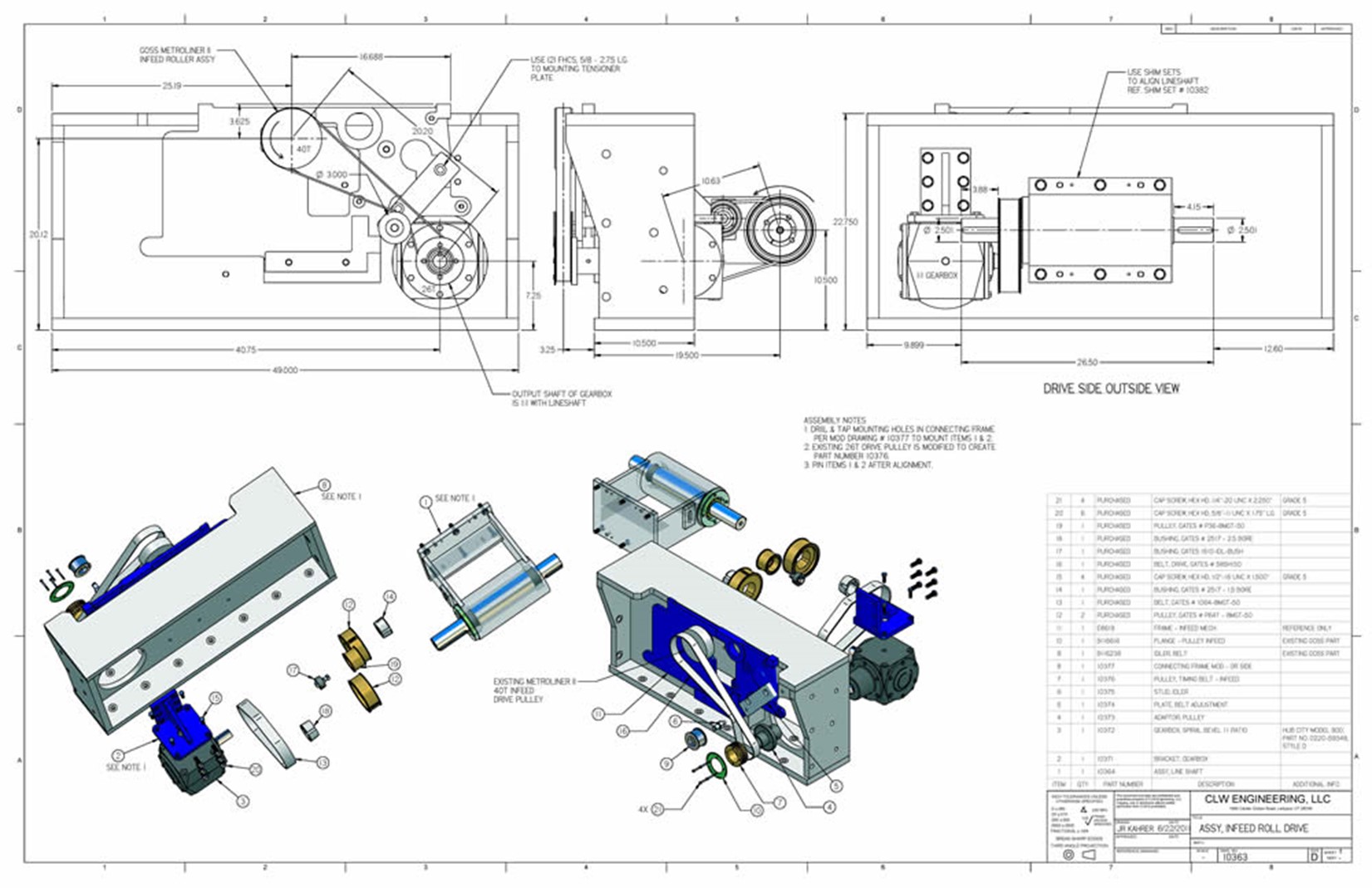

Machine design or mechanical design is the process of drawing the machine or parts of a machine in a 2D or 3D CAD system or, perhaps on a drawing board, to figure out what each part needs to look like dimensionlly in order for it to meet the machine requirements. This is sometimes called a “layout”. From there, detail drawings are made of the parts that need to be made. These “detail drawings” are used by either the internal shop or outside machine shops or fabrication shops and the parts are made to the spec’s, dimensions, material etc.. on these detail drawings. The layouts are generally finished up to create an assembly drawing for the people in the shop or field to assemble all the components or parts. The assembly drawing will contain a list of all the parts required to assemble and build it. Fasteners, parts that were made and parts that where purchased from vendors are listed on the assembly drawing.

CLW Enginering Inc. uses SolidWorks or AutoCad as CAD systems for machine design.

Custom Engineering

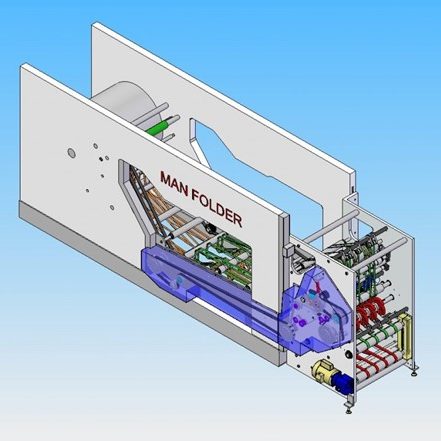

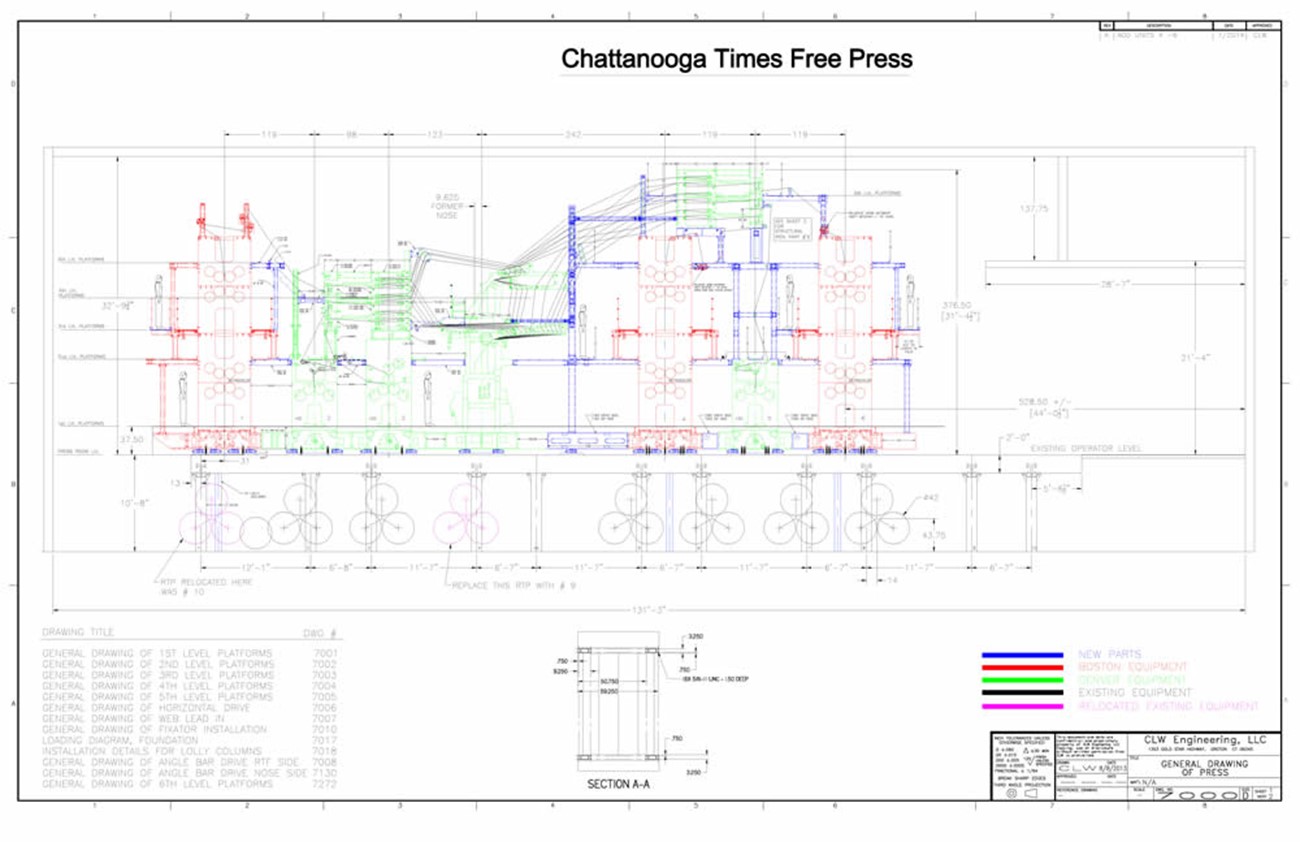

We pride ourselves in engineering your project from a sketch on a napkin through the documentation process, building parts, to a functioning piece of machinery. Below is a double delivery for a Man Roland folder which allowed the customer to run two jobs at once. Designed, assembled and installed by CLW Engineering Inc.

Reverse Engineering

There are times when a piece of equipment needs to be reconfigured or upgraded to meet the ever changing demands or other times when the piece of equipment you need is no longer available. CLW Engineering Inc. can “reverse engineer” your equipment and build a new one.

Drafting & Modeling

2D and 3D CAD Packages available in AutoCAD 2016 or Solid Works 2016.

Printing Press Engineering

CLW Engineering Inc. did all the Press Engineering to install GOSS HO Units and GOSS MetroColor Towers on existing HOE substructure and reels.

Automation

No Responses